Large agricultural machines increase productivity in farming, but also compact the soil to the detriment of harvest quantity and quality. Seven Dutch farmers set off on a search to a solution for this problem and together, they created a new innovation. In collaboration with the Machinefabriek Boessenkool, Wissels Techniek and Van Ham Organisation & Consultancy, they developed the Multi Tool Trac. The Multi Tool Trac is an electrically-powered tractor for efficient and sustainable agriculture. The system tractor reduces the amount of work for farmers and increases the yield.

The vehicle

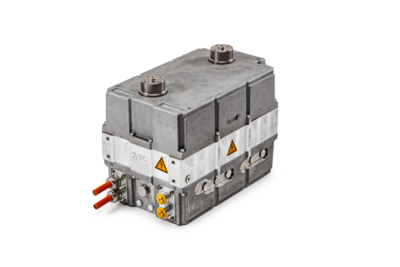

The Multi Tool Trac is an equipment carrier with a completely electrical drive line, and a modern 6-cylinder diesel engine with 140 kW (185 PS) as range extender. The diesel drives an STW-powerMELA C 140kW generator which supplies the drive and all on-board consumers. Sensor-Technik Wiedemann GmbH (STW) has supplied components for mobile electrical hybrid systems for years.

“The Multi Tool Trac is the first electrical system tractor which makes agricultural work easier and more sustainable, and which retains the natural soil quality in its optimum form“, explains Managing Director Paul van Ham.

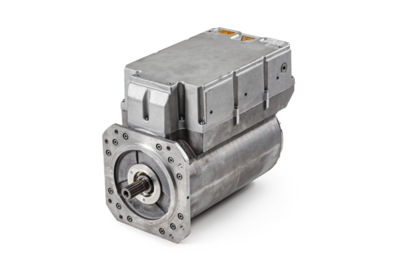

A 30kW/h traction battery is connected for work of up to half an hour in the field. The modern Li-Ion battery is able to double the power of the complete drive for a few minutes, thus providing the vehicle with increased thrust power. The four wheels, which are equal in size, are powered by one electrical wheel hub motor and one reduction gear unit each. A permanently excited synchronous motor has a continuous output of 22 kW, and can be driven with a maximum power of 44 kW. The driver can steer the machine easily in any situation using a joystick, and can thus carry out all work accurately. All four wheels are steerable, thus permitting a particularly small turning radius.

All standard commercially available attachments can be mounted onto the three mounting frames (rear, front and between the axes) on the very long frame and within the field of view of the driver. This prevents the driver from developing neck or back complaints when in the centre position, as it is no longer necessary to check the attachments by frequently turning round to look at them.

A unique, variable chassis permits the track width to be changed between 2.25 and 3.25 m, and thus increases the efficiency on the field and the safety on narrow country roads.

Sustainable working of the soil

In order to make the best of the fertile ground, the vehicle is designed for the soil processing procedure «Controlled Traffic Farming» CTF. With CTF, exactly the same driving track is used each year. The precision GPS steering (RTK support), the tractor can always be positioned in the same track on the field, which optimally protects the soil and minimises soil compaction. The soil which is not driven on remains loose, thus ensuring optimum plant growth and high profitability.

Technical data:

- Electrical drive with 4 x 22 kW rated power and 4 x 44 kW maximum power

- Battery/rechargeable battery capacity: 30 kWh

- Range extender: modern six-cylinder diesel engine with 140 kW (185 PS) with an efficient high-speed powerMELA generator.

- Steering: Fully-electronic steering with GPS RTK, prepared for autonomous driving

- Devices: 3 full-quality mounting positions for three-point linkage and PTO shaft

- 4 powered wheels for a tight turning radius and optimum traction under all conditions

- Cabin: Stepless cabin, can be moved back and forth to permit two additional superstructure spaces

- Track adjustment on-the-fly, adjustable between 2.25 to 3.25 metres

wheelbase 5.50 metres - Load capacity: 5 tonnes

Fuel consumption

"In comparison to a normal tractor, we are able to save 20 percent fuel with the Multi Tool Trac", says Managing Director Paul van Ham. This is made possible through intelligent power management. The different operating modes mean that the tractor can run emission-free. The battery feeds the entire drive system. If the battery is empty or more power is required, the diesel engine with generator is connected. The diesel engine is operated in an optimum degree of efficiency range at as low a speed as possible. It merely serves to provide the required energy for the vehicle. Here it is mechanically completely decoupled and there is no direct dependency between the diesel engine speed, the travelling speed and the PTO shaft drive.

Dietmar Schrägle from STW adds: “The electrical drive, with its substantially improved degree of efficiency in comparison to conventional tractor drive lines, lowers energy costs, reduces emissions and makes a direct contribution to environment protection”.

Fuelling from the socket

The use of wind, sun and biomass to supply energy presents major challenges to our society. Agricultural businesses are increasingly playing a key role as energy providers. An electrical, battery-operated tractor which utilises power from regenerative energy sources is gentle on the environment and on our climate. It is particularly efficient if the generated power is consumed directly on location, instead of it having to be conducted via long mains cables. In future, it is also feasible that the tractor could act as a flexible energy centre for agricultural businesses. For example, during periods when the tractor is not working, milking machines and cooling units could be supplied from the battery.

Market launch

The two Multi Tool Tracs which have been built up to now are currently in use by farmers involved in the syndicate in Holland. After successful field tests, the vehicle is to be extended with new features to fulfil additional requirements.

The first affordable electrical tractor is more expensive than a standard vehicle. “Due to the many new functionalities, the high yield from harvesting and the fuel savings, this investment immediately amortises itself”, says Paul van Ham.

Information updates can be viewed under www.multitooltrac.com.