Avoiding unplanned downtimes and maximizing process efficiency is essential in agriculture. The newly developed BCX.4cs-ag Body Control Unit from STW helps machine manufacturers and operators achieve these goals.

Body control units manage the distribution and regulation of electrical energy within a vehicle and in combination with an implement. Electrical consumers, such as heaters and lights, can be switched and controlled directly be the body control unit. The automation specialists at STW have developed a body control unit that is optimized for the requirements of agricultural machinery. The BCX.4cs-ag supports the bidirectional communication required for Tractor Implement Management (TIM) with ISOBUS and so facilitates the realization of smart farming applications.

With Tractor Implement Management, the implement provides the tractor with the optimum parameters for the process, such as the best driving speed or the required power from the hydraulic system. The tractor acts as an automated power supply in the overall system. For the machine operator, this means improved process quality and efficiency, as the system optimizes itself and only demands the power that is currently required. Such assistance systems significantly reduce the expertise required to carry out the process. Particularly in view of the shortage of skilled operators, this can make a decisive contribution to the efficiency of agricultural operations.

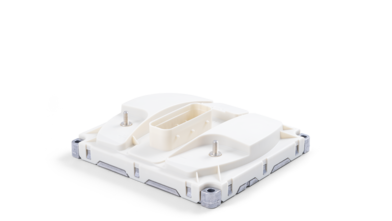

With ten high-side outputs, two low-side outputs, CAN interface and eight 10 A half bridges, the machine manufacturer has a wide range of communication and control options at his disposal. Sensors can be supplied with 5 to 12 V, and the BCX.4cs-ag is protected against the impact of dirt and moisture with a protection class of up to IP6K9K. The design allows operation even under the most severe vibrations and shocks, and the housing is resistant to typical aggressive media. The operating temperature range is from -40 to 85 °C. With dimensions of only 212 x 192 x 50 mm the BCX.4cs-ag fits into the tightest of installation spaces and lends itself to the design of compact machines. In addition to the ISOBUS TIM functionalities, machine manufacturers and operators can benefit from the monitoring and diagnostic functions of the BCX.4cs-ag. With continuous current monitoring, preventive maintenance measures can be taken before damage occurs. This reduces unplanned machine downtime: a major advantage, especially in time-critical harvesting phases.

STW will present the newly developed BCX.4cs-ag body control unit at Agritechnica 2023 in Hanover.

![[Translate to Chinese:] [Translate to Chinese:]](/fileadmin/_processed_/f/4/csm_Logo_41f8d03cbf.jpg)