CLOUD SOLUTIONS & ON-BOARD SOFTWARE

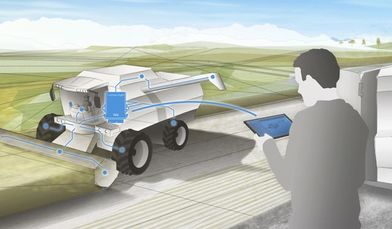

Using the system module MACHINES.x, we are paving the way for the digitalization of mobile machines, and thus for the different manifestations of Industry 4.0 in applications over and above typical industrial systems.

MACHINES.x unites the specific requirements of very different machines in municipal technology or the agricultural or construction industry through a combination of interlinking modules. Appropriate solutions are realized through open, standardized interfaces using data and interconnected computers on the machines, software modules on vehicles and a Cloud platform.

Our range of services includes the analysis of the interests of the machine manufacturer, taking into account all parties involved as well as the recording of the ecosystem surrounding the machines. From this, a digital strategy can be defined for the manufacturer, which is initially supported by a prototype. MACHINES.x facilitates the supply and evaluation of these initial results from the prototype within a few months or weeks, depending on the complexity.

MACHINES.x is expanding the horizon of Industry 4.0 with the integration of mobile machines. The system module permits “Rapid Prototyping” and allows this subject, which is still highly abstract to many, to be experienced. In connection with the analysis of interests, not just the technical implementation can be illuminated, but also targets can be determined with regard to a digital transformation. MACHINES.x can be scaled depending on the respective company size, and offers the advantage of independence from the provider.

The modular principle of MACHINES.x and the associated services offer you a simple and rapid entry point (“Proof of Concept”) into the world of Industry 4.0 whilst integrating all relevant parties involved. Using the vehicle TCG hardware and “MACHINES.access”, developers and service teams can obtain direct remote access to the control units on the mobile machine. Data is visualized, preprocessed and update roll-outs are carried out across the entire fleet. Over and above this, the IoT solution MACHINES.cloud permits the control of complex processes and permits the clear depiction of relevant data for end users. Large quantities of data are assessed using "MACHINES.analytics". Algorithms derived from these assessments facilitate edge computing on the TCG modules and therefore also "Predictive Maintenance". The use of machine and process data thus permits business models, the basis for which is no longer the machine as such, but rather the service it provides.

CASE STUDIES

While we are proud of our products and solutions, it is through our customers’ applications that the power in the innovative technology is unleashed. Whether fully networked, highly automated, or operating fully autonomously, an effective mobile machine represents first class interdisciplinary engineering. Robust and safe integration into the system architecture of the machine and its work processes, while remaining convenient and user friendly, is the main focus. With thanks to our customers, here we would like to present a small selection of example applications.

STW USPs

We support our customers as a partner for the digitization and automation of mobile machines and the related work processes. Our comprehensive and highly interoperable STW modular system of high quality sensing, control and software products ensures a problem free integration in the final application.

As experts in all aspects of functional safety, we offer services in high level automation in the field of mobile machines, including autonomous functions and driving. Our STW ecosystem includes a comprehensive partner network of system integrators and distributors to ensure an optimal solution for every application, worldwide.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/f/1/csm_m-analytics_18bab5449a.jpg)